Land application of biosolids is considered a safe practice in Ontario when managed in accordance with the Nutrient Management Act (NMA), O.Reg 267/03. The NMA was developed by the Province of Ontario to provide for the management of materials containing nutrients in ways that will enhance protection of the natural environment and provide a sustainable future for agricultural operations and rural development. Excessive amounts of nutrients, which are present in biosolids, fertilizer and manure, can produce negative impacts on the environment. Despite over 30 years of research which show that, when conducted according to regulations, land application of biosolids is safe, concerns remain over soil and groundwater contamination from trace elements, toxic chemicals and potentially harmful disease causing organisms (pathogens). To date, there have been no documented negative human cases where a biosolids program met all the provincial requirements. The NMA provides specific requirements for nitrogen, phosphorus, metal and pathogen concentrations that must be met before biosolids can be land applied. Finally, odours associated with the land application of biosolids are considered more of a nuisance than a health problem. Odours are often times the most objectionable aspect of biosolids use on neighbouring farms.

All restrictions are conservatively set to prevent toxicity or health impacts in plants, animals and humans.

Groundwater contamination

The Nutrient Management Act provides minimum regulated standards to protect groundwater. These standards are in place to prevent nutrients that are present in biosolids from leaching into ground water table through infiltration. The NMA states that there must be a depth of at least 0.9 meters of dry soil when applying biosolids to prevent nutrients from leaching into groundwater.

The amount of biosolids applied to the soil is also restricted by soil type. This prevents biosolids from moving quickly in the soil. Soil types such as sand and loam have a high infiltration rate large soil particle sizes and drain very quickly. When applying biosolids to sand, application rates must be limited to ensure no seepage to ground water occurs. However, soil types like clay and clay loam have poor infiltration rates due to small particle sizes to which biosolids are more likely to be retained within the rooting zone of the field.

The NMA also provides restrictions when applying biosolids to areas with exposed bedrock. Bedrock that is too close to the soil surface can cause poor infiltration and pose a higher risk for ground water contamination. For this reason, there must be at least 0.9m of soil above bedrock.

Biosolids also contain unique properties which inhibit leaching to groundwater. These properties include charged particles, bacteria, and pathogens that bond to organic matter in the soil. When bacteria and pathogens bond to soil particles, they are less likely to enter ground water and can be broken down by soil microbes, sunlight and weather.

For more information on groundwater please visit the Ontario Ministry of Natural Resources page here.

For detailed information on runoff processes, infiltration and soil texture classifications please visit the University for Atmospheric Research page here.

Surface water contamination

Biosolids, like any fertilizer, binds to soil particles which may enter nearby streams and surface water during heavy rainfall events.

All nutrients that are applied to a field should follow Best Management Practices and/or regulation by establishing buffer zones to surface water. These nutrients include manure, commercial fertilizer, anaerobic digestion materials, old feedstocks, NASM and other agricultural source materials.

Regulations are in place to prevent water pollution by biosolids. Both BMP’s and NMA instruct applicators to maintain buffers along surface water areas like streams and municipal ditches.

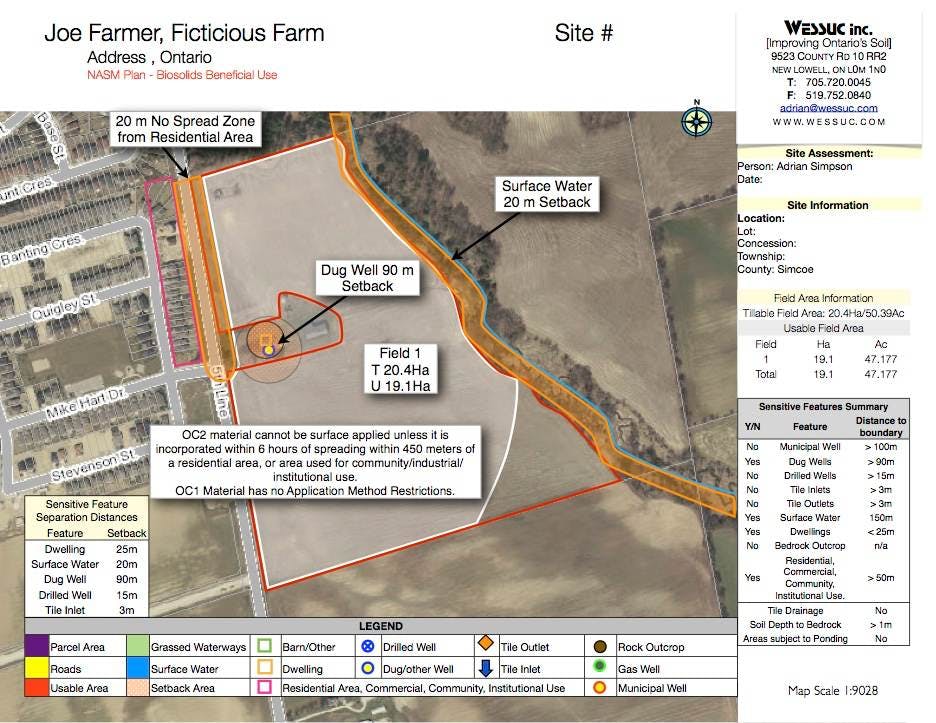

The regulations enforce a minimum separation distance of 20 meters between the biosolids application area and surface water.

Slopes near surface water also restrict application rates. Application of biosolids is prohibited on slopes over 12 % which are located within 150 meters of surface water. This ensures that biosolids would not have direct access to surface water due to runoff.

Water pollution is also prevented by maintaining lower application rates on clay and clay loam soils. Clay soils usually have a low permeability which can present a higher risk of runoff which can greatly affect waterways. To prevent this from happening, lower application rates and methods can be used to allow biosolids to infiltrate more rapidly into the soil.

As well, biosolids cannot be applied to land that is snow covered or frozen. Snow covered and frozen ground can prevent biosolids from being incorporated or retained in the soil effectively. This may result in biosolids movement off of the field and into the waterway.

Application methods like direct injection, pre-application tillage, and immediate incorporation greatly reduce runoff potential.

Click here for more information on the runoff process.

Can biosolids make me sick?

A major public health and environmental concern associated with land application of biosolids is the effect of pathogens on humans and animals. Like any manure, biosolids contain microorganisms that should not be ingested. Pathogens are disease causing organisms such as bacteria, parasites, and viruses.

The potential for exposure diminishes over time as environmental conditions such as heat, sunlight, desiccation, and other microorganisms destroy pathogens that may be present in biosolids. In order to be approved for land application, biosolids must be treated to reduce the number of pathogenic organisms. This treatment will reduce the level of bacteria and viruses by 95% and reduce parasitic content by 66%.

To minimize the potential risks during application, legislation requires a setback to be established between the application area and any wells or surface water that are located within specific distances. These setbacks are strictly enforced. A mandatory waiting period between biosolids application and cropping or pasturing acts as a safety precaution.

A common misconception is that the pathogens in biosolids are more harmful then the pathogens in animal manure. Biosolids have been spread for over 50 years with no documented evidence of causing harm to human health.

Toxic chemicals

Certain toxic chemicals that do not volatilize or decompose during treatment may concentrate in biosolids. Therefore, the best environmental solution is prevention. The Municipal Act, 2001, gives municipalities the authority to enact sewer use bylaws to regulate what and how much is discharged into their sewer systems. Depending on the municipality, these bylaws may set limits on just a few basic parameters, such as temperature and pH, or they may set out rules for a long list of pollutants. In some cases they may require sewer users to think about changing manufacturing processes, reformulating products, or finding ways to capture and reuse wastes. In many cases, industries have found that pollution prevention projects tend to pay back in a short time.

Items of proof: Residues from chemicals have greatly declined over the past 40 years. Benzene, for example, was detected in 93% of biosolids samples in a survey conducted during the late 1970's, but in only 3% of samples from the late 1980's. Detection of persistent pesticides such as chlordane, dieldrin, heptachlor, and hexachlorobenzene were detected in 16% of the 1970's samples, but none of the 1980's samples. These declines are due to pretreatment, chemical bans and the phasing out of chemicals.

Do biosolids smell?

Yes, biosolids can smell. Most odours associated with the biosolids are reduced during the treatment process, but as the organic materials break down, odours are released. The method of application also has an effects on odour, injecting biosolids below the soil surface helps to minimize potential for odours. In most cases, odours dissipate after several days, similar to animal manure. The Nutrient Managemnent Act has divided the many different types of NASM into 3 odour categories; OC1, OC2, and OC3. OC1 has the least amount of odour and OC3 has the most. Different odour categories have different separation distances to dwellings, residential areas, or areas used for community /commercial / Institutional use. Depending on the odour category your application methods may also be restricted. The restrictions are found in the NMA regulations point 47. Biosolids are categorized as OC1 and OC2 (see site map example).

What about heavy metals?

Historically, industries disposed of their liquid wastes in to the sanitary sewer system, causing high metal concentrations where highly industrialized cities and places existed. Since the late 1970’s, sewer use by-laws have been established, as well as pretreatment requirements to reduce or remove metal constituents before they enter the sanitary sewer system. The by-laws have been very effective in decreasing metal inputs into wastewater treatment facilities.

Metal mobility and availability to plants can increase under certain conditions; inorganic and organic components, to which metals are usually linked, are more easily dissolved in acidic soils, to minimize this, the NMA requires a minimum soil pH value of 6 or greater and requires testing of the 11 regulated metals in the soil and biosolids product prior to land application. The 11 regulated metals are Arsenic, Cadmium, Chromium, Cobalt, Copper, Lead, Mercury, Molybdenum, Nickel, Selenium and Zinc. The NMA provides a table outlining the maximum addition to soil and the maximum concentration in soil for each of these metals. Some metals, such as Copper, Molybdenum, Nickel, Selenium and Zinc are essential micronutrients for plant growth, but are only required in minute amounts.

Concentrations of regulated metals in biosolids are consistently well below regulation standards.

Tanker trucks are used to deliver liquid biosolids to fields. The tanker trucks that haul liquid biosolids generally hold 43 cubic meters (10,000 gallons). A field that is spread with an average application rate would receive 3 truckloads per hectare (2.5 acres). Therefore, a 10 hectare (25 acre) field could receive an average of 30 truckloads during the application event.

Truckers are required to abide by local county transportation requirement. Haulage routes are developed to avoid residential roads whenever possible. Also, land application operations usually occur during regular working hours in order to minimize any potential inconvenience caused by the trucks.