Safety first

At Wessuc, we place the safety of our team and those around us above all else. Every project we do, no matter how small, is executed with safety first mindset from start to finish. It only takes one safety error to result in an accident. At Wessuc that is one accident too many. Wessuc has an in-house Health & Safety team to ensure that all safety measures are followed, safety certificates are up to date, and staff training is done properly.

We Are Hard COR

Wessuc is certified under COR (Certificate of Recognition) through IHSA (Infrastructure Health & Safety Association), a distinguished and elite designation in health and safety compliance, recognized by the Canadian Federation of Construction Safety Associations. It's another step in showing our devotion to safety in everything we do.

Wessuc is certified under COR (Certificate of Recognition) through IHSA (Infrastructure Health & Safety Association), a distinguished and elite designation in health and safety compliance, recognized by the Canadian Federation of Construction Safety Associations. It's another step in showing our devotion to safety in everything we do. COR is aimed at driving positive workplace behaviour and practices that lead to improved performance. The Certificate Recognition is nationally trademarked and is endorsed by participating members of the Canadian Federation of Construction Safety Associations.

To learn more about COR click here.

WSIB

Wessuc is certified under WSIB (Workplace Safety Insurance Board). The health and safety of our employees is our top priority and we ensure all situations get addressed accordingly with the board.

Wessuc is certified under WSIB (Workplace Safety Insurance Board). The health and safety of our employees is our top priority and we ensure all situations get addressed accordingly with the board. Wessuc is always continuing to learn and take important steps to improve our workplace safety. In 2021 we completed the WSIB Health & Safety Excellence program. We are currently working towards completing this program again for 2022.

To learn more about WSIB click here.

HHCA

Wessuc is a member of the Hamilton-Halton Construction Association (HHCA), which is a full-service construction association that has been operating for 100 years. The HHCA serves the needs of their members and the community by promoting excellence in structures and safety in the Hamilton and Halton regions. This is just another step in showing our dedication to safety within our company.

Wessuc is a member of the Hamilton-Halton Construction Association (HHCA), which is a full-service construction association that has been operating for 100 years. The HHCA serves the needs of their members and the community by promoting excellence in structures and safety in the Hamilton and Halton regions. This is just another step in showing our dedication to safety within our company.To learn more about the HHCA click here.

Wessuc Training

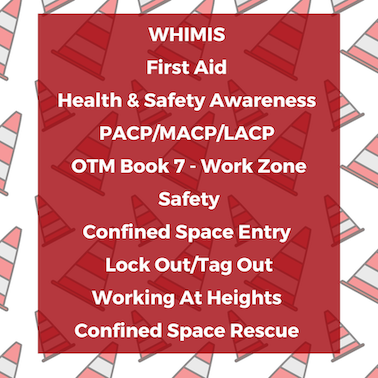

Wessuc ensures all employees are properly trained before even stepping foot onto a job site. Training is coordinated in-house through Wessuc's Health and Safety team, and tracked through the Wessuc Work Hub app, which is entirely paperless as a way to minimize our effect on the environment. The Work Hub app also stores all certifications which makes it easier for Supervisors and the Health & Safety team to be able to pull up any employees training certifications. The app also alerts the Health & Safety team when an employee needs to retake a certification that has expired which helps our crews stay up to date on all their safety training requirements. One of the great features Work Hub has is that Wessuc crews get points when completing training through the app, and with those points they can redeem prizes. This reward system has made getting our crews to complete training a lot more enjoyable and created a higher training completion rate. Depending on an employee's position they may require other training to be able to safely perform their job. A list of certifications that our employees may have are listed in the image.

Wessuc ensures all employees are properly trained before even stepping foot onto a job site. Training is coordinated in-house through Wessuc's Health and Safety team, and tracked through the Wessuc Work Hub app, which is entirely paperless as a way to minimize our effect on the environment. The Work Hub app also stores all certifications which makes it easier for Supervisors and the Health & Safety team to be able to pull up any employees training certifications. The app also alerts the Health & Safety team when an employee needs to retake a certification that has expired which helps our crews stay up to date on all their safety training requirements. One of the great features Work Hub has is that Wessuc crews get points when completing training through the app, and with those points they can redeem prizes. This reward system has made getting our crews to complete training a lot more enjoyable and created a higher training completion rate. Depending on an employee's position they may require other training to be able to safely perform their job. A list of certifications that our employees may have are listed in the image.PPE

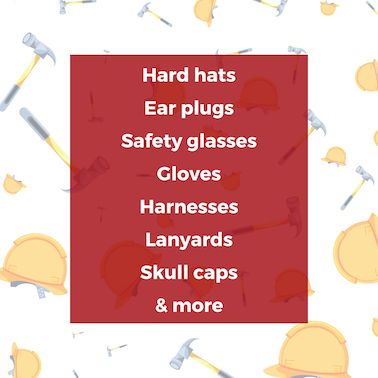

PPE is a vitally important part of safety at Wessuc. Depending on the job and the work environment some PPE would be mandatory while others may be recommended.

A piece of PPE that all Wessuc employees must wear at all times on a job site is steel toe footwear, there is zero exemption for this. Other PPE items that Wessuc crews have are listed in the image.

Weather

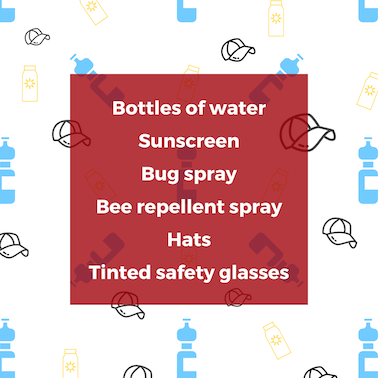

Our Health & Safety Coordinator Paul Richardson talked about the extreme heat that we are facing this summer.

“As Heat waves increase in Canada and our climate continues to change, making sure our employees can work outside safely is a top priority. Wessuc’s Health and Safety program ensures workers onsite have access to adequate drinking water, PPE, policies, and active monitoring of the upcoming forecasts. Sunburns, heat stress, fatigue, dehydration, can all be avoided if everyone at Wessuc continues to play their part with regard to safe work practices in the field.”

Winter months also require proper tools and equipment as ice, snow and cold temperatures cause a safety risk. Staff are provided with: road salt, shovels, insulated gloves, and toques.

Mental Health & Harassment

At Wessuc we fully support all of our staff that vocalize any mental health concerns or issues. Our Health & Safety team will offer resources that employees could look into for further help and continue to support and communicate with them as long as they require.

There is a zero tolerance for harassment and bullying at Wessuc. We are a safe environment for our workers and will not allow anyone to feel endangered or unwelcome in our facilities. We take harassment and bullying claims very seriously and ensure that every situation is investigated thoroughly and immediately.

Safe Driving

Wessuc has an extensive fleet of heavy duty trucks that require a proper drivers license to operate. Employees are trained on how to drive and operate the vehicles before being allowed to fully work on them on their own. Even if an employee isn’t the one driving the vehicle they still require training on how the vehicle operates and the proper safety signals and procedures that come with the vehicle.

Wessuc employees that work on job sites are trained on OTM Book 7 - Work Zone Safety, which is the safety procedures of traffic setup. In many cases our crews are working on roadways that can at times be busy with traffic. It is vitally important that our crews know how to safely set up in traffic not only for their safety, but the safety of other drivers. Especially with the summer months upon us the roads have started to get busier with cars and cyclists. We encourage our staff to review the OTM Book 7 - Work Zone Safety to ensure they are fully up to date on the proper procedure of traffic set up.

A portion of Wessuc fleet vehicles are equipped with ELD’s (Electronic Logging Device) which is used to track hours of services and safety. This system allows Supervisors, Project Managers, Health & Safety team and HR to be able to track Wessuc work trucks for safety reasons and see how many hours of work the truck has done. At the moment not all of our fleet have ELD’s in them, but our Health & Safety team is working on getting them installed in every Wessuc vehicle to comply with the ELD commercial vehicle mandate taking effect in 2023.

For more information on the mandate of ELD’s in commercial vehicles click here.

Lock Out/Tag Out

Lock out/tag out is a protection system used to inform workers about not using a certain piece of equipment and/or machinery. The difference between a lock out and a tag out is the device used. A lock out device is a padlock that allows other employees to know they cannot operate the equipment/machine, essentially this is the first layer of protection against unsafe equipment. A tag out device is a tag that informs other employees that the equipment/machine should not be operated, a second layer of protection. All Wessuc employees get their own lock out locks and tag out tags. This ensures that all employees have access to labeling equipment or machinery that is deemed unsafe.

Wessuc Safety Policy

At Wessuc we are always improving and updating our safety policy to ensure it stays up to date with our company and industry. We strive to implement procedures to decrease the risk of any and all accidents before they happen. When talking about the unknown safety risks that are within our industry, Richardson replied “When it comes to being safe, it’s worth remembering Murphy’s Law: Anything that can go wrong will go wrong.”, which is exactly why Wessuc takes safety so seriously. If/when an accident occurs and we don’t have a safety procedure in place within our policy, our Health & Safety team immediately looks into the situation and ensures it gets added to the safety policy in case of future incidents.

For reference an employee at Wessuc was in an accident attempting to tow a piece of equipment and resulted with them getting injured. The Wessuc Safety policy didn’t have any safety procedures regarding proper towing protocols, but is being implemented to decrease the chance of a towing accident occurring again. When asked about the accident Richardson said “It is essential that our equipment operators recognize the real dangers associated with pulling application equipment, tractors, or trucks out of mud, sand, or snow. Extracting equipment is anything but routine, and owners and operators need to understand the potential repercussions of unsafe practices (such as of using a cut towing strap, undersized clevis or chain, or a weak attachment point). Such shortcuts can lead to expensive repairs, injuries that last a lifetime, or worse, a person’s death.” We are currently creating a safe job procedure for towing. As our equipment continues to expand, age, get stuck, a clear and effective towing procedure is imperative for our workers to operate safely.”

Learn More

We take health & safety extremely seriously here at Wessuc. Our saying is that all employees go home safe every night. For more information on safety at Wessuc click here.

+1 519 752 0837

+1 519 752 0837